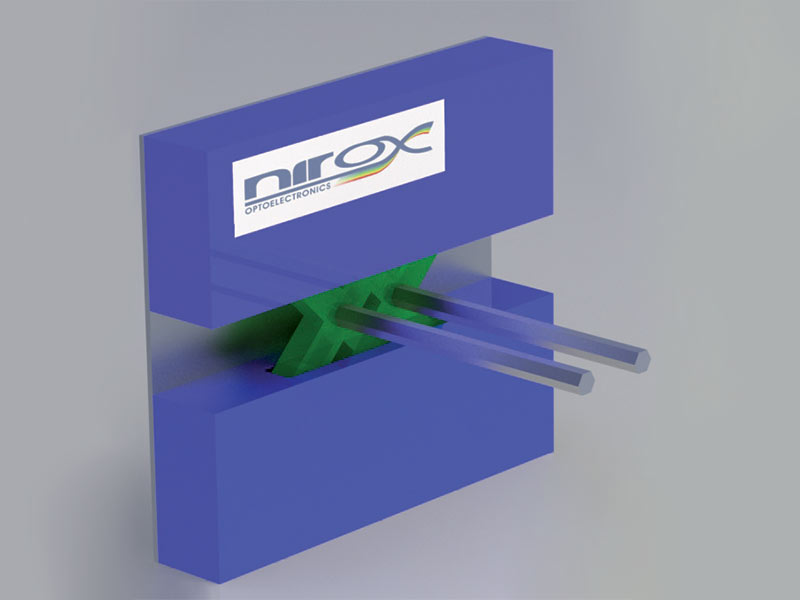

Measurement systems for metal industry

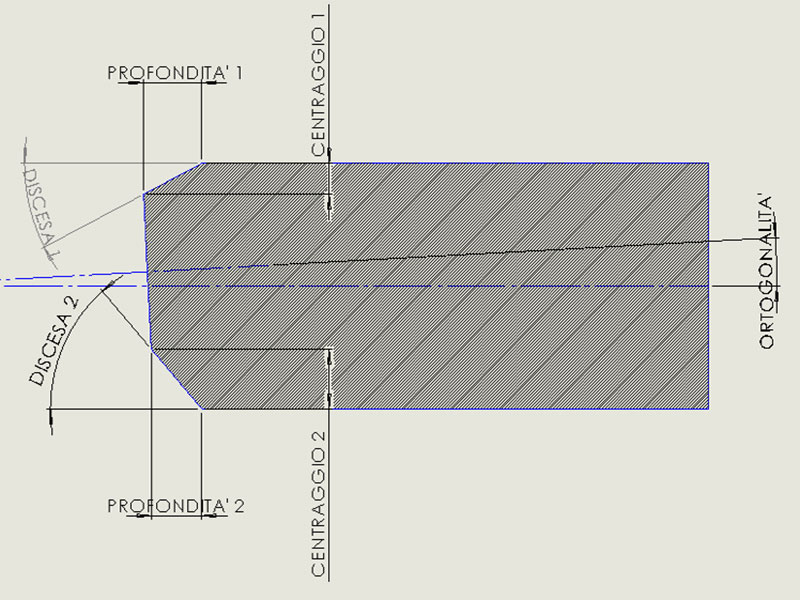

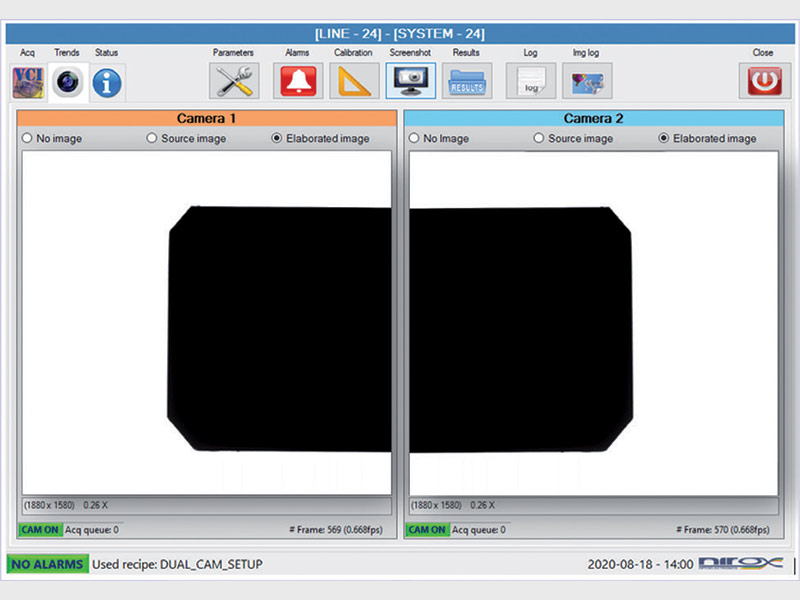

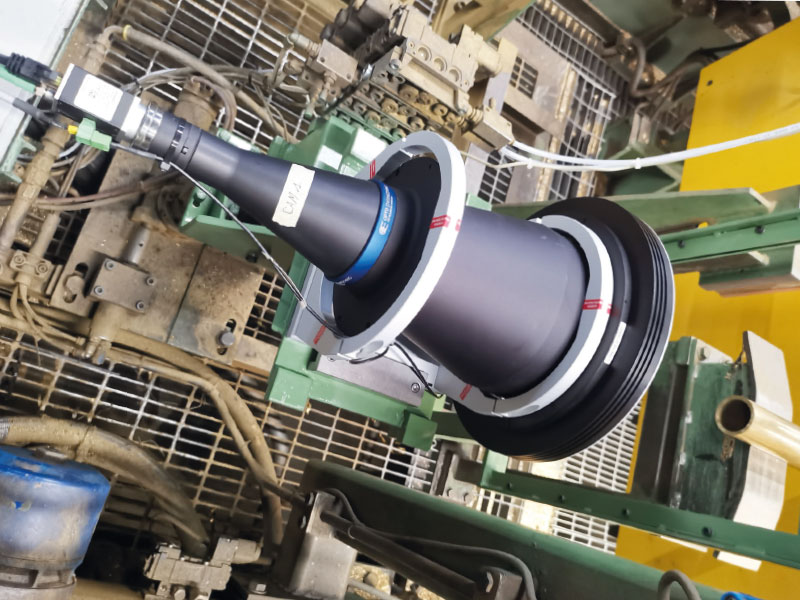

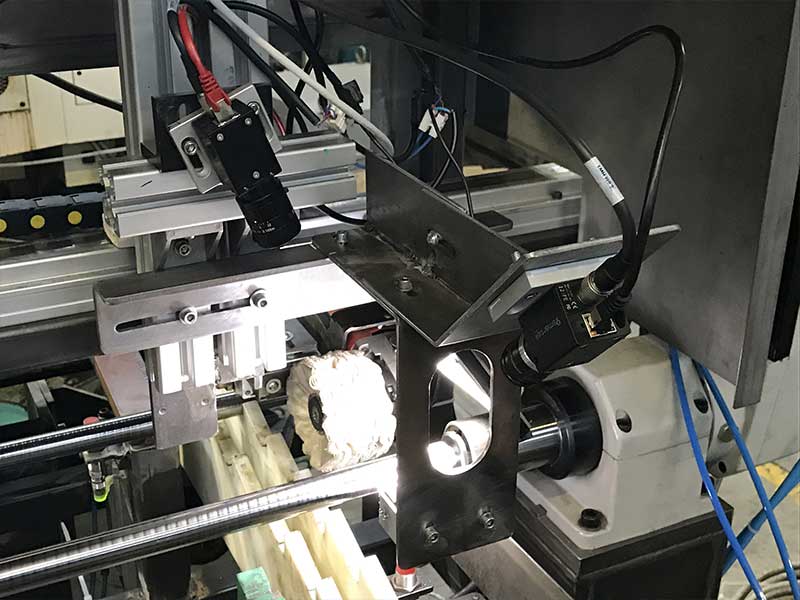

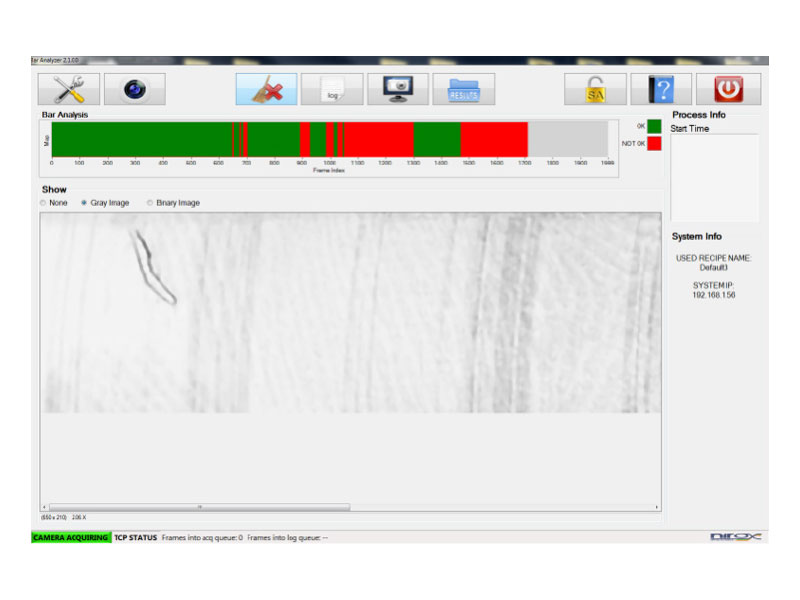

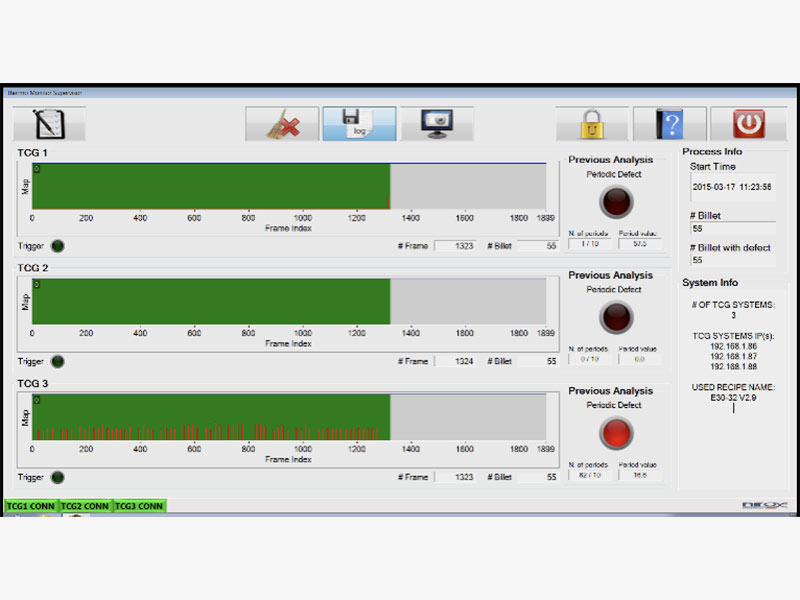

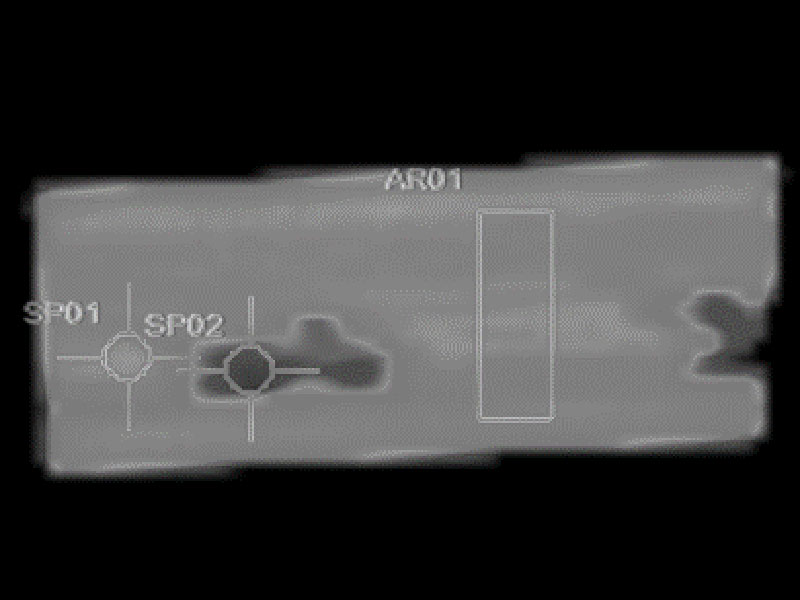

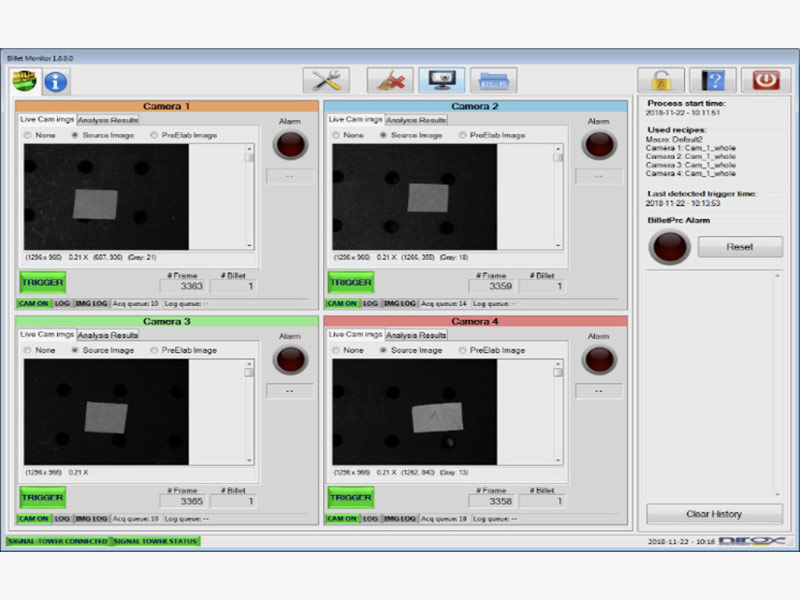

Metal parts can present complex structures and generally request the highest measure precision and product quality to be compliant for the following manufacturing processes. They are often produced at very high temperatures, thus making the measuring process difficult. NIROX’s optical instruments for metal are designed to measure and detect possible defects during production and in extreme environmental conditions.