Measurement systems for plastic industry

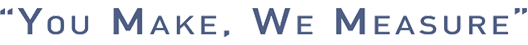

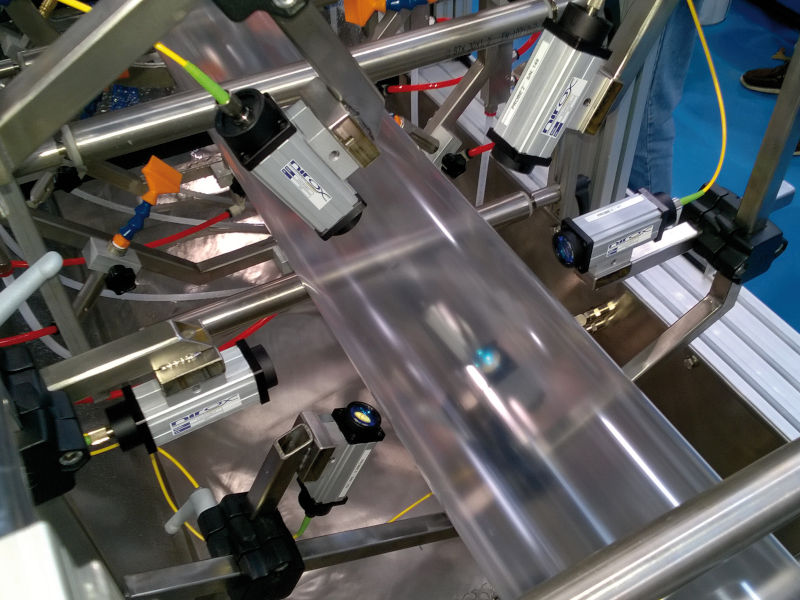

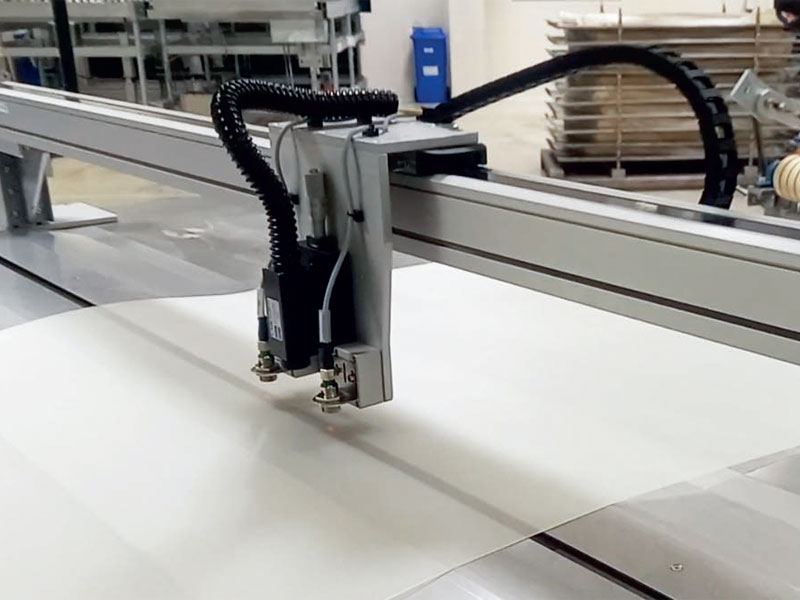

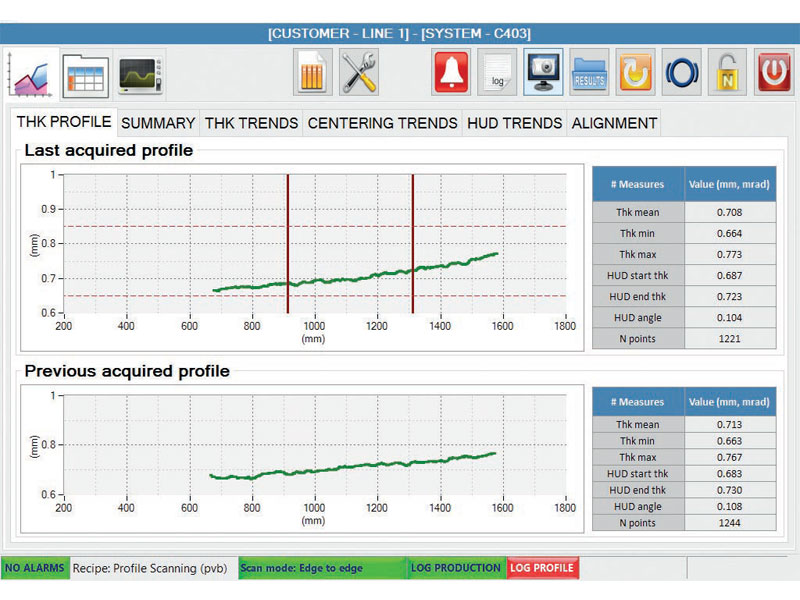

Plastic production processes require the most accurate and quick inspections and measurements, which must be easily integrated into the production line.

NIROX’s optical instruments for plastic allow to measure various parameters constantly and directly in line, without altering the process, in order to guarantee that specifications are respected in the entire production batch. Instruments can be placed in QA/QC laboratory, as well.