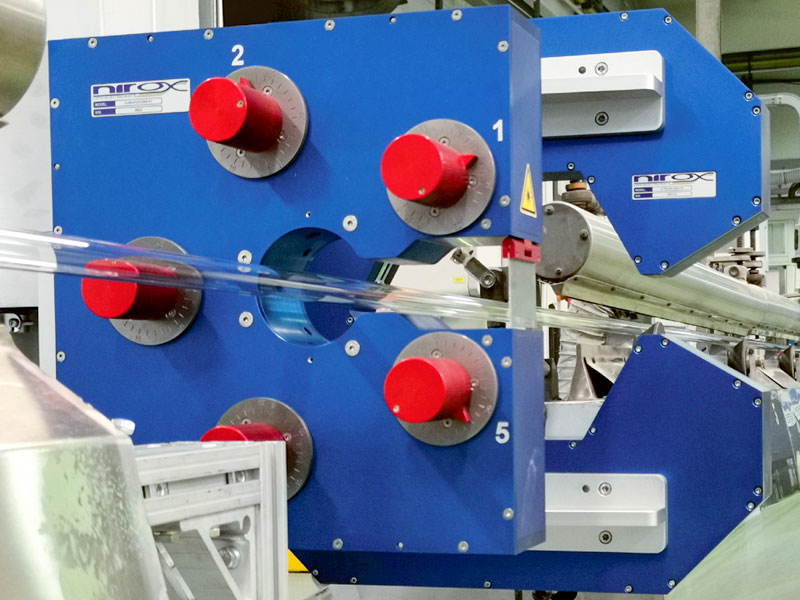

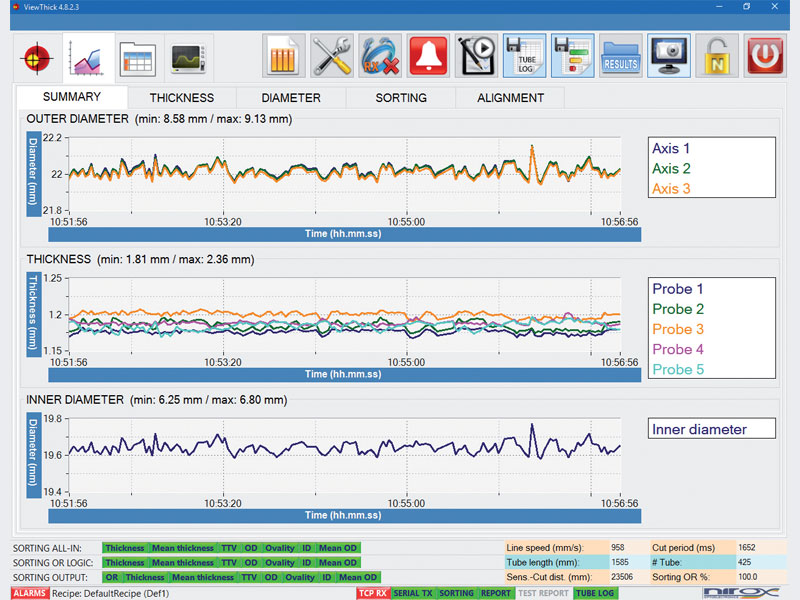

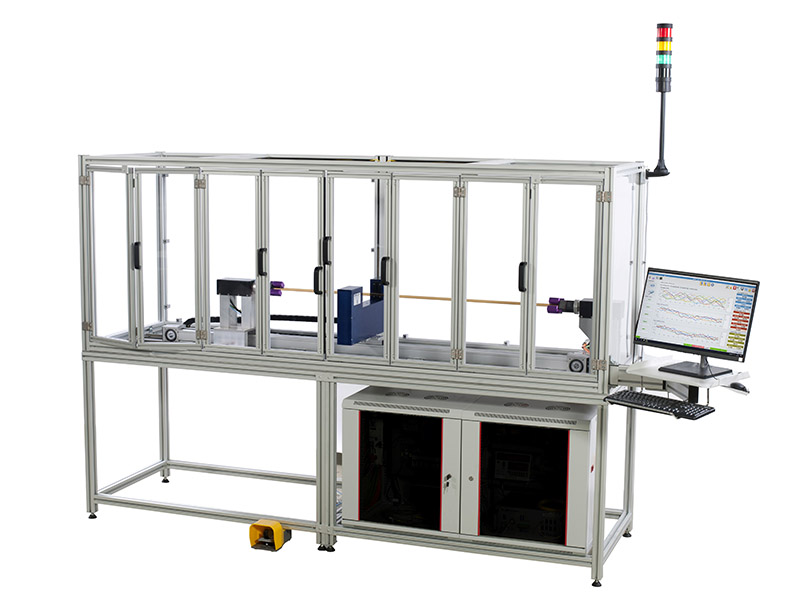

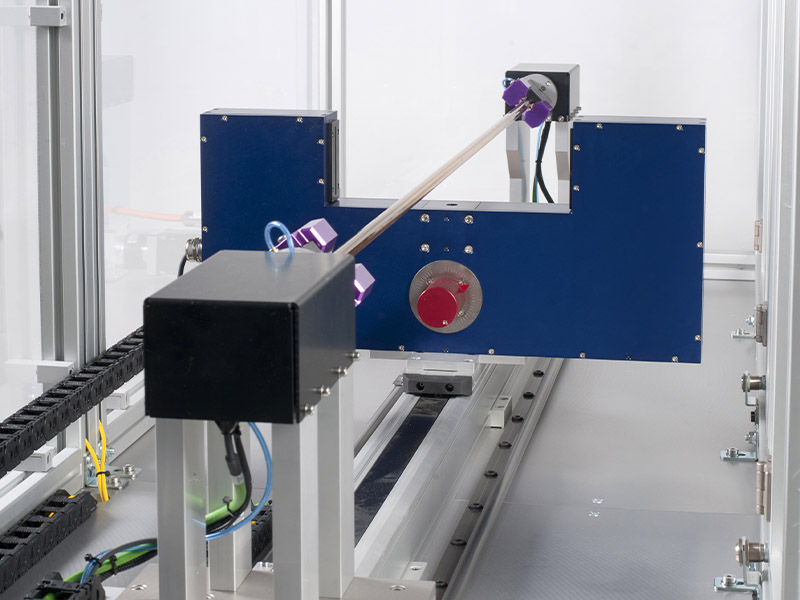

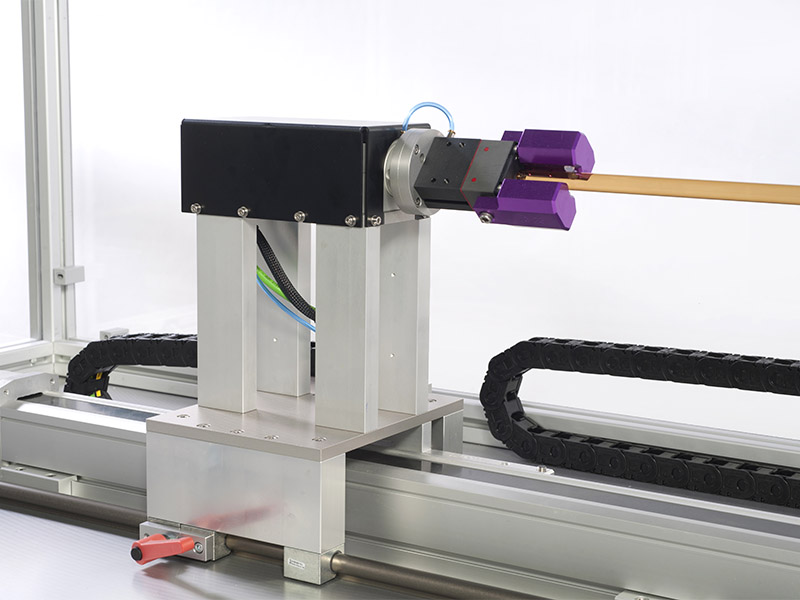

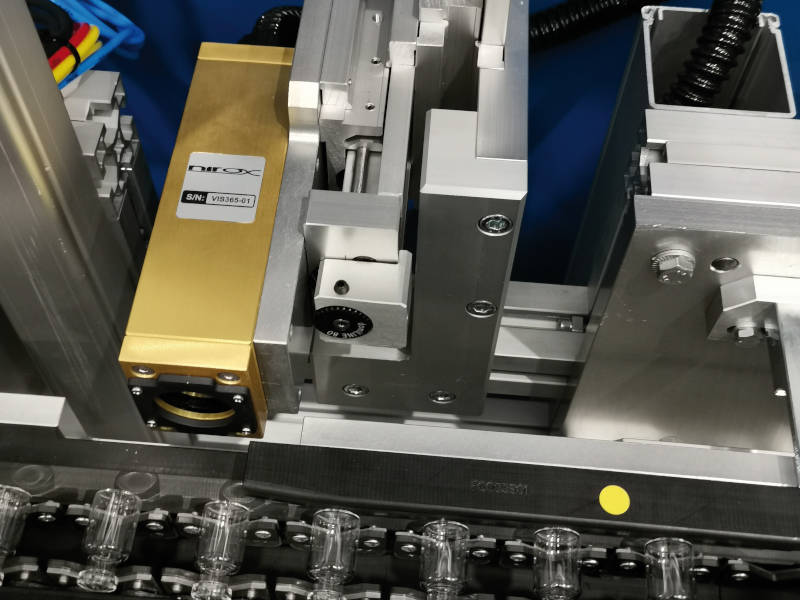

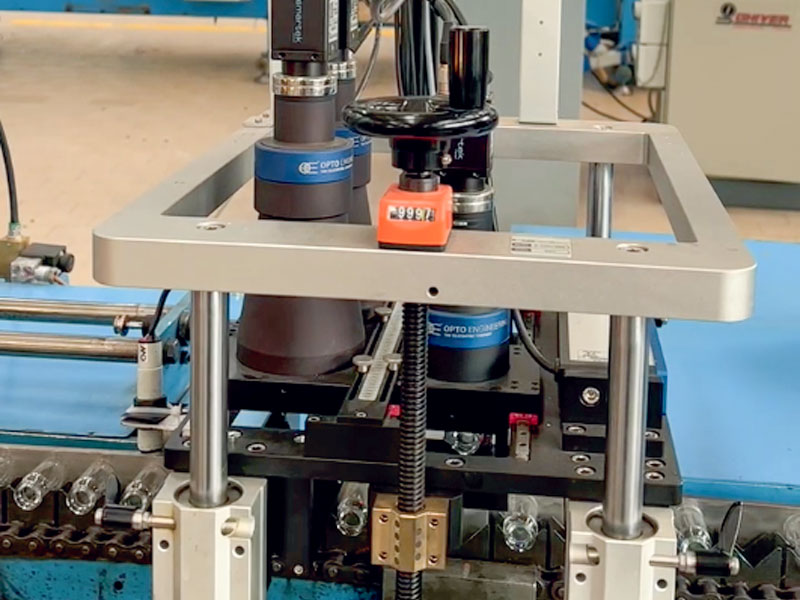

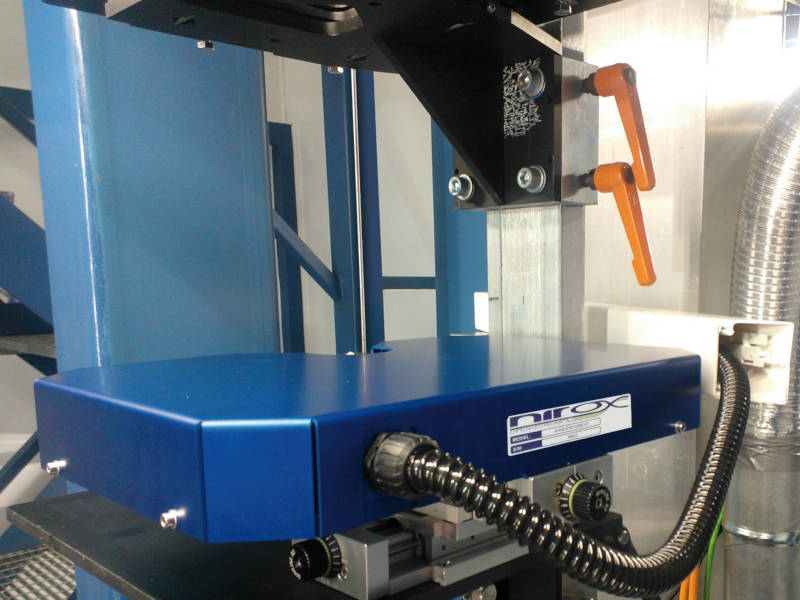

Measurement systems for glass industry

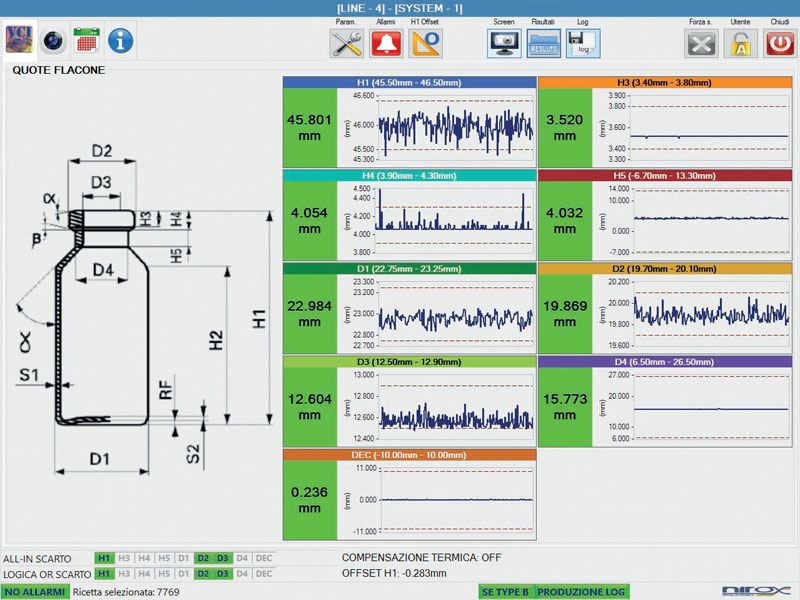

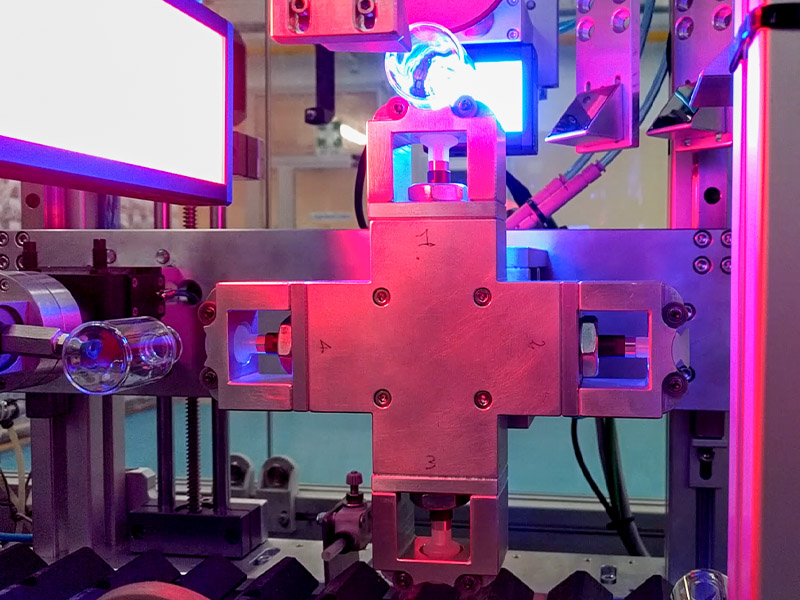

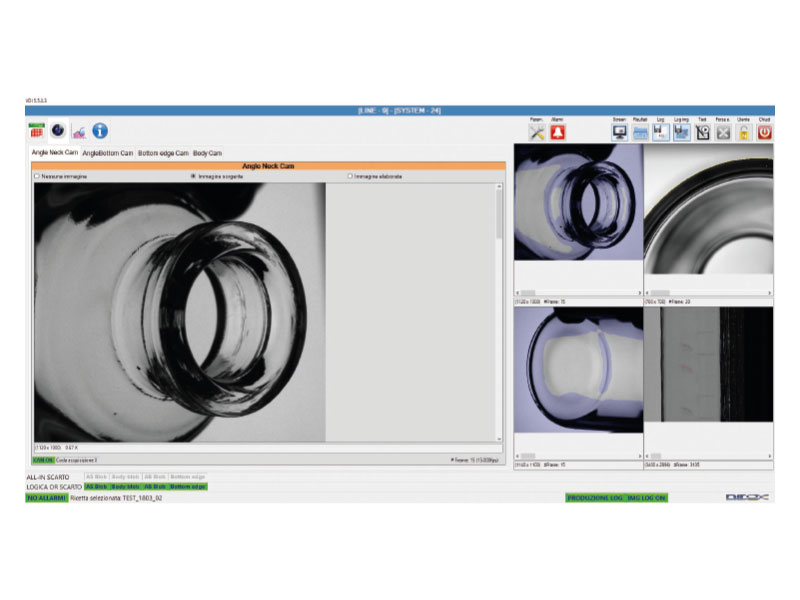

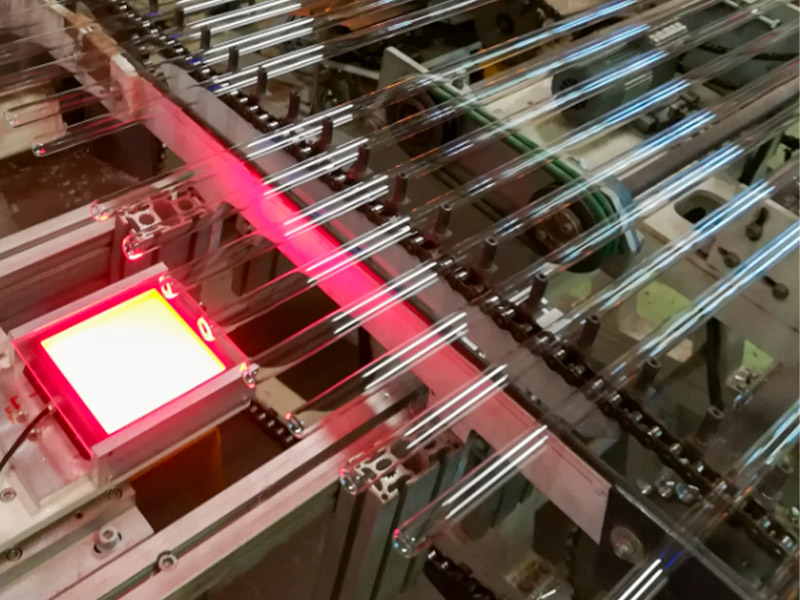

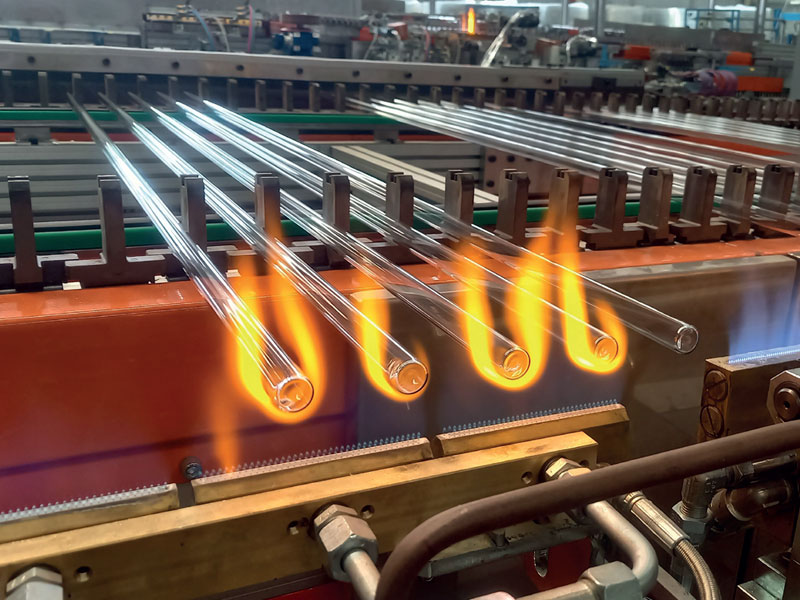

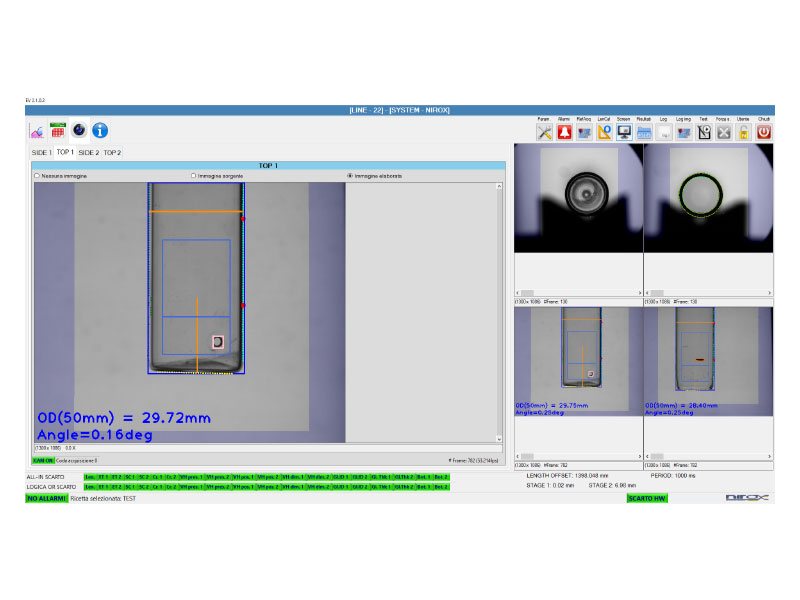

Glass products, often used for food, pharmaceutical and safety applications, need absolute respect of dimensions required by the end-user. The laboratory QA/QC sample testing cannot grant the quality of the whole production batch. NIROX’s solutions for Glass industry, suitable for various steps of production chain, allow to measure without stopping or slowing down the process, and to grant the specifications for the entire lot.